Design

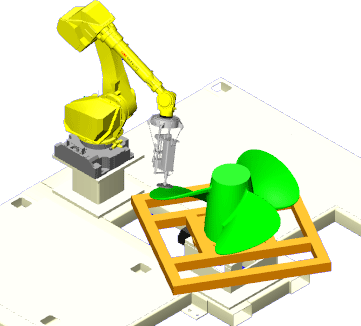

The design process of the end effector body starts from defying the machining application. Capabilities of the robot and the stock materials affect which materials and components should be used.

The position and angle of the spindle changes the robots reach. With steep angle, you can reach farther in planar parts, but in complex parts more gradual angle gives better results.

Production

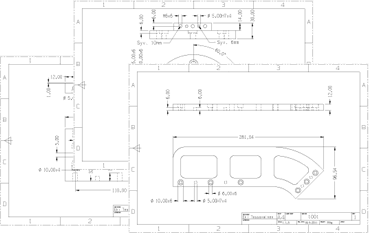

When the desing is ready, all the drawings and 3D-models are sent to the our machine shop. Our contracting chain consist companies with high experience in this field. After machihing all the parts are inspected and the body is test assembled.

When everything is ready and all the parts have arrived, the package is sent to the customer. You will have to get in contact with a local electrician to do the high voltage connections. Your local robot-dealer can do the I/O connections.

Programming

We can do robot programming to customers 3D files or accurate drawings. We use Mastercam and Robotmaster for programming and simulation.

You can conntact your local dealer for more details.

International Mastercam site: www.mastercam.com

International Robotmaster site: www.robotmaster.com