Spindles

We can use varioty of spindles to create optimum package. In many solutions, the most crucial criteria is tool conection and weigth.

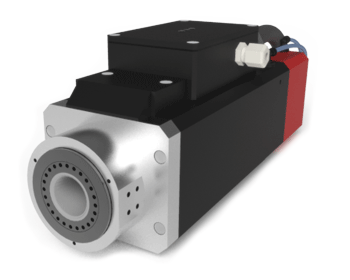

Small spindles range from 350 watts with ER11 collects to 2,2 Kw with ER25 collects. Medium spindles (picture) are from 3,6 Kw to 7,2 Kw and they have ISO20 - 30 holders with automatic tool changer. Large ones can have dozen kilowats and ISO- or HSK-holders.

Most robot solutions doesn't require high power spindles, since robots can't handle high tooling forces. Our prefered spindle is the 3,6 Kw with automatic tool changer and air- or liquid cooling.

Electronics

All the electronics are tailored to support the selected spindle. When a higher RPM spindle is selected, the frequency inverter needs to match the spindles maximum frequency. Other variables are used voltage, number of phases and the required power.

Commonly used voltages and maximum outlet power is different in other countries. This factor will be also taken into account in the selection process.

The spindle speed can be changed programmatically or by a control knob. Manual control switch for the automatic tool changer can be also installed, if customer prefers to change tools by hand.

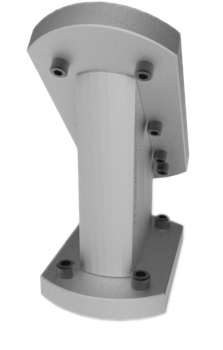

Spindle bodies

Most common materials are Romax, stainless steel and aluminum. Different materials and designs can be used when light weight or rigidity is desired.

The effector body is modular, which gives the possibility to use the same body partially in different setups. This generates savings, if the robot or the spindle is changed afterwards.

All the 3D-models and drawings are kept securly to ensure spare part production. When the spare part is needed fast, we can contract a local machine shop to produce the needed part.